Mastering the Rcf Centrifuge A Step by Step Tutorial for Optimal Performance

Table of Contents

- Understanding the Basics: What the Rcf Centrifuge Does and Its Key Components

- Choosing the Right Rotor: Types, Capacities, and Material Considerations

- Optimizing Your Protocol: Key Parameters for Centrifugation Speed and Time

- Troubleshooting Common Issues: Effective Solutions for Enhanced Centrifuge Performance

- Maintaining Your Rcf Centrifuge: Best Practices for Longevity and Reliability

- Enhancing Diagnostic Efficiency: Insights from Recent Hematology Market Trends and the Role of the Automatic 5-Part Hematology Analyzer MX60

- FAQS

- Conclusion

- Related Posts

When you're working in biotech or medical diagnostics, getting a good handle on the Rcf Centrifuge is pretty important if you want your lab work to go smoothly. Here at Zhejiang Pushkang Biotechnology Co., Ltd., we’ve been around since 2014, and we really take pride in being a high-tech company focused on R&D and manufacturing in vitro diagnostics (IVD). Our specialty lies in centrifugal microfluidics, and we’ve rolled out point-of-care testing (POCT) products in areas like coagulation, biochemistry, CLIA, and molecular diagnostics—all thanks to our solid tech platform. This tutorial is here to walk you through the basics of using the Rcf Centrifuge effectively. Our goal is to help you get a better grip on your lab work, making things more efficient, and ultimately supporting the push toward better diagnostics with our innovative solutions. Hope you find it helpful and easy to follow!

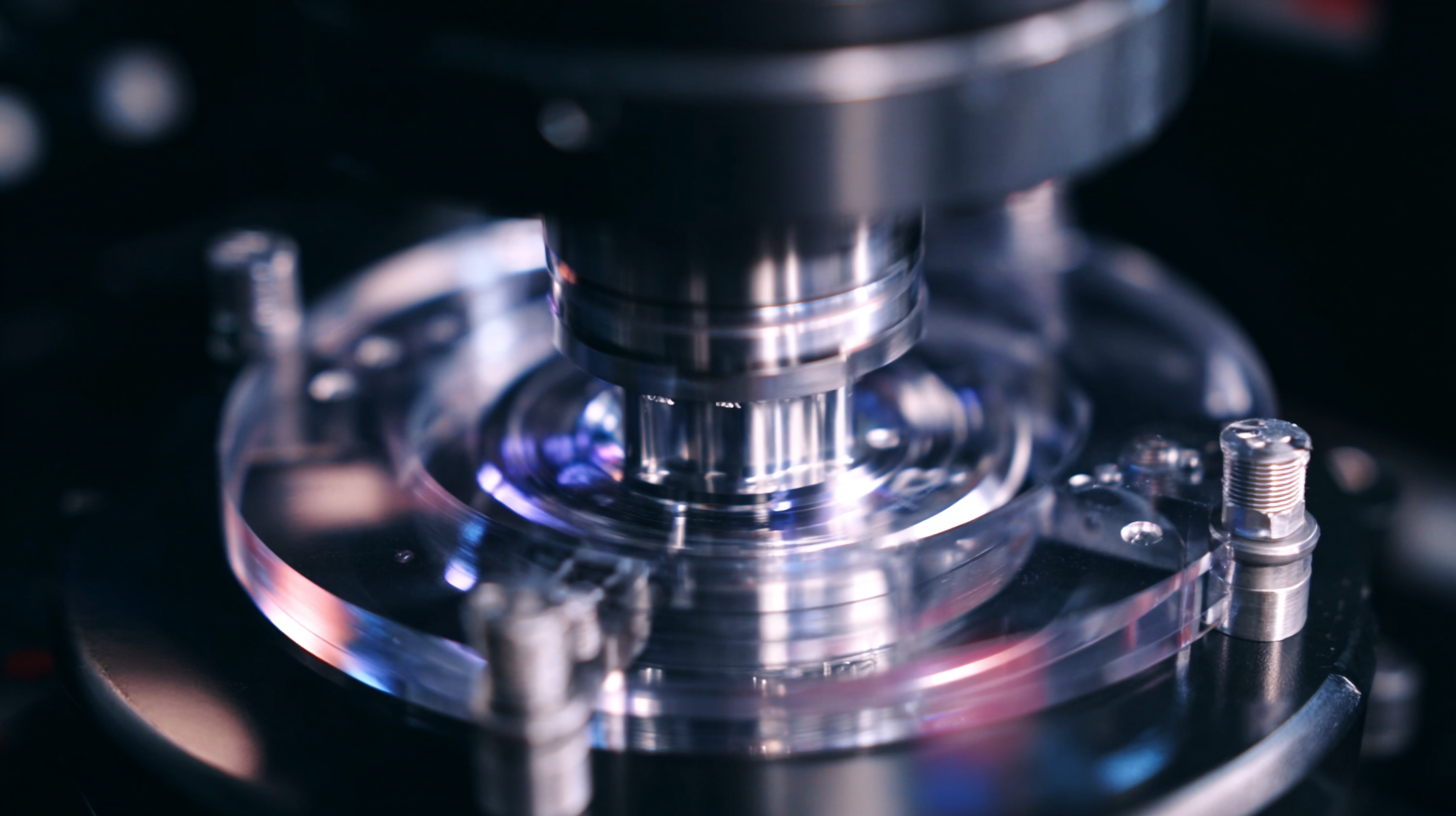

Understanding the Basics: What the Rcf Centrifuge Does and Its Key Components

The RCF centrifuge is a pretty essential tool in labs, especially when it comes to in-vitro diagnostics (or IVD for short). If you're working with these machines, it’s really important to get a good grasp of how they work—that way, you can make sure they perform at their best. So, what exactly is RCF? Well, it stands for relative centrifugal force, and basically, it tells you how intense the force is that's pushing on your samples during centrifugation. This force depends on how fast the rotor spins and how far out the samples are from the center. That’s why understanding this stuff is crucial—whether you're doing blood clotting tests or biochemical analysis, it helps produce accurate and consistent results.

Now, a typical RCF centrifuge has a few key parts. There's the rotor, which holds your sample tubes; the drive system that controls how quickly and smoothly everything spins; and the control panel, where you set the parameters for your specific experiments. At Zhejiang Pushkang Biotechnology Co., Ltd., we're proud to use cutting-edge centrifugal microfluidics technology to create point-of-care testing devices that boost the precision of molecular and CLIA tests. By really understanding how to operate the RCF centrifuge and knowing what each part does, you’re set up for better performance. That means more reliable data, improved diagnostics, and happier labs all around.

Choosing the Right Rotor: Types, Capacities, and Material Considerations

When you're picking out the right rotor for your RCF centrifuge, it’s pretty important to understand the different types, capacities, and materials involved—because that’s how you get the best performance out of your lab work. There are a few main kinds of rotors, like fixed-angle and swinging-bucket, each suited for different tasks. For example, fixed-angle rotors are great if you’re doing pelleting or sedimentation—they spin faster and help concentrate your samples more quickly. On the other hand, swinging-bucket rotors are better when you need more precise separation across a broader range of sample densities.

Finding the right capacity comes down to how much sample you’re working with and what kind of throughput you need. Fun fact: using the right rotor can boost your sample yield by up to 30% — which is a game-changer when it comes to efficiency. Plus, don’t forget about the materials—aluminum and titanium are common choices, and they really influence how durable your rotor is and whether it can handle high speeds. If you're running high-speed spins regularly, investing in titanium might be worth it because it’s super strong and lasts longer.

**Here are a few quick tips:**

1. Always double-check with the manufacturer’s specs so your rotor matches your centrifuge model—safety first, right?

2. Make it a habit to inspect your rotors regularly for any signs of wear and tear. It’s a simple way to avoid contamination and keep your experiments consistent.

3. Think about what your specific lab needs and the types of experiments you’re doing—that way, you’ll pick a rotor that really works for you and keeps things running smoothly.

Mastering the Rcf Centrifuge: Choosing the Right Rotor

| Rotor Type | Max Capacity (mL) | Max RCF (×g) | Material | Applications |

|---|---|---|---|---|

| Fixed Angle Rotor | 50 | 21,000 | Aluminum | Pelletizing, Cellular Studies |

| Swinging Bucket Rotor | 250 | 10,000 | Plastic | Density Gradient Centrifugation |

| Fixed Angle Micro Rotor | 2 | 30,000 | Carbon Fiber | Small Volume Samples |

| Beckman Type Rotor | 80 | 45,000 | Titanium | RNA/DNA Extraction |

| Temperature Controlled Rotor | 100 | 15,000 | Stainless Steel | Virus Production |

Optimizing Your Protocol: Key Parameters for Centrifugation Speed and Time

When you're working with centrifugation, getting the right balance of speed and time is super important if you want good results. Basically, the force your samples experience depends on how fast the rotor spins, usually measured in revolutions per minute (RPM). Different samples need different settings—like, if you're dealing with sensitive biological stuff, you’d want to keep the RPM lower so you don’t damage the cells. On the other hand, if you’re trying to sediment heavier particles, cranking up the speed is usually the way to go. Figuring out that fine line between speed and keeping your samples intact is key to getting things right.

Then there’s the matter of how long you spin. The duration can really impact how well things separate and how much of your target you recover. Spin too short, and you might not get full separation, but if you go way too long, you risk compacting your pellet and losing some of your sample. The trick is to tweak both the speed and time, sort of like a little experiment of your own, to find what works best for your specific protocol and samples. With some careful adjustments and keeping an eye on things, you’ll see better consistency and results in your centrifuge work.

Mastering the Rcf Centrifuge: Optimization of Speed and Time

This chart illustrates the optimal parameters for centrifugation in terms of speed and time. The speed is measured in gravitational force (xG), while the time is in minutes. Proper optimization of these parameters is crucial for achieving the best performance in centrifugation processes.

Troubleshooting Common Issues: Effective Solutions for Enhanced Centrifuge Performance

When it comes to centrifuge tech, troubleshooting those common glitches can really make a difference in how well things run—especially in setups with high-cell-density mammalian cultures. Using continuous solids discharging centrifugation is actually a game-changer; it helps make the cultures clearer and more resilient. And guess what? Studies show that this kind of efficient separation can bump up your yields by as much as 25% in bioprocessing. Not too shabby, right? This kind of innovation not only boosts productivity but also helps tackle the usual problems that come with traditional centrifugation, which can struggle under those dense cell conditions.

On top of that, adding in some advanced membrane tech takes things even further. For example, newer centrifugal membrane filters like the Ortho-Centrifugal Membrane Filter (O-CMF) are designed to keep pressure steady, so you avoid a lot of the headaches old-school filters give you. It’s pretty timely, too—especially with the global push toward sustainable energy. Some reports suggest that these kinds of membrane improvements could cut water treatment energy use by up to 30%. So, by overcoming these tech hurdles, labs and industries can work more efficiently and be more eco-friendly at the same time.

Maintaining Your Rcf Centrifuge: Best Practices for Longevity and Reliability

Keeping up with regular maintenance on your Rcf centrifuge isn't just about making it last longer—it's key to keeping it running smoothly and getting reliable results every time you use it. Honestly, a little bit of cleaning and checks can go a long way. For instance, make sure you’re routinely cleaning the rotor and inside of the centrifuge. If you leave residues from previous runs, they can throw off the balance and mess with the precision of your next experiment. It’s best to use proper lab-approved cleaning agents and soft cloths — nothing too harsh or abrasive.

And don’t forget about inspections! Take a moment to look over the rotor and the lid for any signs of wear or damage. If anything’s out of whack or showing signs of deterioration, it can pose safety risks or lead to inaccurate results. Double-check that everything’s aligned right and functioning properly. Keeping a record of your maintenance routines and noting any issues that pop up can really save you hassle down the road—troubleshooting becomes way easier. Follow these simple steps, and you’ll keep your Rcf centrifuge in top shape—delivering consistent, reliable performance for all your lab work. Honestly, a little effort goes a long way to ensure everything runs smoothly!

Enhancing Diagnostic Efficiency: Insights from Recent Hematology Market Trends and the Role of the Automatic 5-Part Hematology Analyzer MX60

The hematology market is experiencing a dynamic shift towards efficiency and accuracy, driven by the need for faster diagnostics and better patient outcomes. Recent trends indicate an increasing reliance on automated technologies in clinical settings, with blood analyzers like the MX60 leading the charge. The MX60’s compact design and advanced capabilities, such as its dual acceleration flow cell system, allow for rapid and precise complete blood count (CBC) testing, which is crucial for timely decision-making in patient care.

Data from industry reports highlight that automation in hematology can improve diagnostic accuracy by up to 30%. The MX60 harnesses the latest innovation in tri-angle laser scattering technology, which enhances counting precision. This improvement is particularly significant for differentiating between various white blood cell types, a task vital for diagnosing a range of hematological conditions. By utilizing two separate channels for white blood cell differentiation, the MX60 delivers reliable information about cell physiology, allowing clinicians to detect anomalies with greater confidence.

The incorporation of a unique chemical dye method further elevates the MX60's capabilities. It enables accurate differentiation of basophils and eosinophils, two key indicators in allergic responses and chronic inflammatory conditions. As the hematology landscape continues to evolve, devices like the MX60 exemplify how innovation can bolster diagnostic efficiency and ultimately improve patient outcomes in clinical practice.

FAQS

: The main types of rotors are fixed-angle and swinging-bucket rotors. Fixed-angle rotors are ideal for pelleting and sedimentation, while swinging-bucket rotors are better for applications requiring optimal separation across a range of densities.

Rotor capacity impacts the sample volume and desired throughput. Using the appropriate rotor can improve sample yield by up to 30%, enhancing the efficiency of laboratory experiments.

Rotors are commonly made from aluminum and titanium. The choice of material affects durability and the rotor's ability to withstand operational speeds, with titanium offering greater strength and longevity for high-speed processes.

Always refer to the manufacturer specifications to match the rotor with your centrifuge model, as this ensures proper compatibility and safety during operation.

Regular maintenance includes routinely cleaning the rotor and centrifuge interior, inspecting for wear and tear, and ensuring proper alignment and functioning of all components.

Addressing common issues through troubleshooting can enhance centrifuge performance, particularly in high-cell-density applications, leading to better yield and efficiency.

Advanced membrane technologies, like the Ortho-Centrifugal Membrane Filter, help maintain uniform pressure and mitigate operational issues, improving overall efficiency and sustainability in processes like water treatment.

Documenting maintenance schedules and tracking issues can aid in troubleshooting and help maintain optimal performance, ensuring the centrifuge operates smoothly and reliably.

Routine cleaning prevents residues from previous runs that can cause imbalances, thus ensuring precision and reliability in future separations.

Efficient centrifuge separation can improve clarity and robustness of mammalian cell cultures, boosting yield by up to 25% in bioprocessing applications.

Conclusion

Hey there! So, in this blog titled "Mastering the RCF Centrifuge: A Step-by-Step Guide for Peak Performance," we're diving into all the essentials you need to get the most out of your RCF centrifuge. We start off by breaking down the basics—what exactly RCF centrifuges are, how they work, and their key parts. It’s like the foundation before you get into the nitty-gritty, right?

Then, we move on to something super important: picking the right rotor. I mean, there are so many options—different types, capacities, and materials—so I’ll walk you through how to choose the best one based on your specific experiments.

Next up, we share some tips for fine-tuning your centrifugation protocols. Adjusting speed and time isn’t just trial and error; we give you some practical advice to optimize those settings for better results. Oh, and if things go wrong, don’t worry—we cover common issues and easy troubleshooting tricks to keep your machine running smoothly.

Finally, we talk about the best practices for keeping your RCF centrifuge in top shape. Regular maintenance isn’t just good for prolonging its life but also crucial for getting consistent, reliable results. Companies like Zhejiang Pushkang Biotechnology—who are into cutting-edge IVD products and centrifugal microfluidics—know how important this is!

Anyway, I hope this helps make everything a bit clearer and less overwhelming—happy centrifuging!