What is the Significance of Centrifuging Examples in Modern Industry

Table of Contents

- The Role of Centrifugation in Separation Processes Across Industries

- Key Applications of Centrifuges in Pharmaceutical Manufacturing

- Centrifugation Techniques: A Comparison of Types and Their Uses

- Impact of Centrifugation on Quality Control in Food Production

- Innovation in Centrifugation Technology: Trends and Future Directions

- Environmental Considerations in Industrial Centrifugation Practices

- Enhancing Animal Health: The Role of the Veterinary Immunofluorescence Analyzer MF100V in Diagnostics

- FAQS

- Conclusion

- Related Posts

In today's industrial world, you really can't overlook the importance of centrifuging examples, especially when it comes to biotech and diagnostics. Centrifugation is such a key player in separating and analyzing biological samples—making lab work quicker and more accurate. I’ve seen reports indicating that the global market for centrifuges is expected to hit around USD 3.5 billion by 2027. That growth’s mainly driven by better healthcare tech and the growing need for diagnostic testing. Companies like Zhejiang Pushkang Biotechnology Co., Ltd., which started back in 2014, have really made a splash by leveraging centrifugal microfluidics technology.

They’ve rolled out point-of-care testing (POCT) products that tackle everything from coagulation and biochemistry to CLIA and molecular testing. In this blog, I’ll walk you through some examples of centrifuging in action, highlighting how these technologies are truly transforming the industry—improving diagnostic precision and, ultimately, patient outcomes.

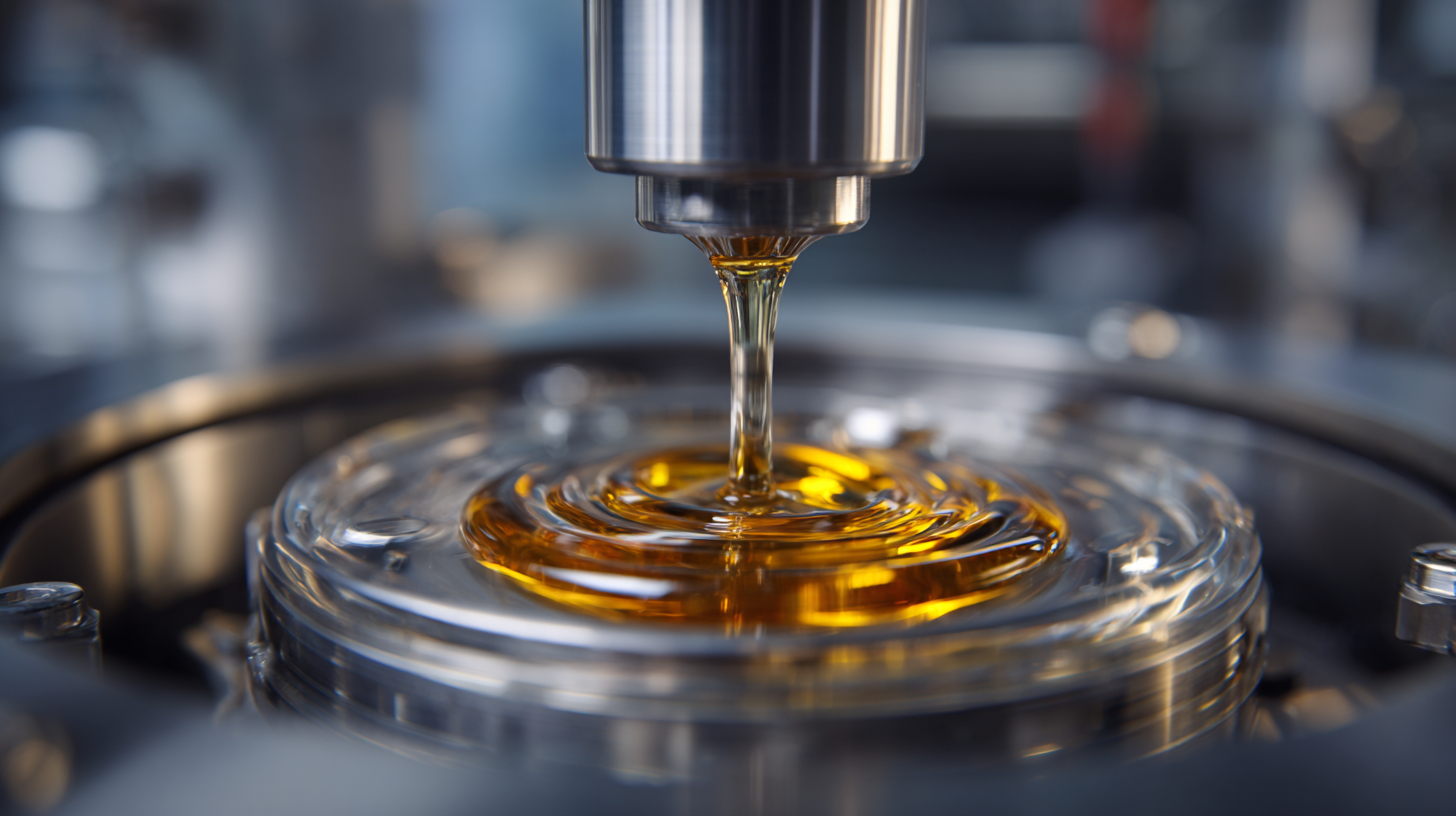

The Role of Centrifugation in Separation Processes Across Industries

Centrifugation is a pretty crucial part of a lot of industrial separation processes. It basically helps to separate liquids, solids, and gases more efficiently. You see industries like pharma and food processing really rely on centrifuges to get their products just right—whether it's making sure medicines are pure or that food stays fresh longer. For instance, in pharma, centrifugation is a must-have for pulling out healthy cells from culture media, which is super important for safety and quality. Over in the food world, it’s what helps separate cream from milk or clear out pulp from juices—things that make a real difference in how good and long-lasting the final products are.

Centrifugation is a pretty crucial part of a lot of industrial separation processes. It basically helps to separate liquids, solids, and gases more efficiently. You see industries like pharma and food processing really rely on centrifuges to get their products just right—whether it's making sure medicines are pure or that food stays fresh longer. For instance, in pharma, centrifugation is a must-have for pulling out healthy cells from culture media, which is super important for safety and quality. Over in the food world, it’s what helps separate cream from milk or clear out pulp from juices—things that make a real difference in how good and long-lasting the final products are.

Now, if you want the best results when using a centrifuge, some tips are worth keeping in mind. First, tweak the speed and duration based on what you’re working with—going faster speeds up the process, but it could also put sensitive stuff at risk, so finding the right balance is key. Also, don’t forget about regular maintenance—making sure the rotors and tubes are clean and not worn out is a simple step that can seriously improve how well the separation works and keep everything safe.

And here’s a little extra—temperature matters too. Some materials can be heat-sensitive, so cooling the samples during centrifugation can help keep everything stable and intact. If you follow these simple tips, you’ll get better results, boost productivity, and improve product quality overall. It’s all about fine-tuning the process and paying attention to the little details!

Key Applications of Centrifuges in Pharmaceutical Manufacturing

You know, centrifugation really plays a huge part in pharma manufacturing. It's basically the go-to method for sorting out different parts of biological and chemical mixes efficiently. This tech is especially important when you're working on in vitro diagnostic products, where every second counts and precision is key. Think of it like spinning samples rapidly in a centrifuge to separate blood components, purify proteins, or concentrate samples for testing — all to make sure tests come out super accurate.

At Zhejiang Pushkang Biotechnology Co., Ltd., we’ve built our core tech around centrifugal microfluidics to boost the quality and effectiveness of what we offer. Since starting back in 2014, we’ve incorporated cutting-edge centrifugation techniques into our point-of-care testing devices for things like coagulation, biochemistry, and molecular diagnostics. Not only does this make our processes more efficient, but it also helps us deliver quick results, which is really a game-changer given how fast healthcare needs are growing.

Pro tip: When you're picking out centrifuges for pharmaceutical stuff, pay attention to things like rotor speed, capacity, and what kinds of samples you'll be dealing with. And don’t forget — regular calibration and maintenance are essential to keep things running smoothly and ensure your results stay reliable. Keeping these factors in mind can really help improve productivity and maintain top-notch quality in your lab.

Centrifugation Techniques: A Comparison of Types and Their Uses

Centrifugation is honestly a pretty essential technique in today’s industry, especially when it comes to biotech and diagnostics. There are a bunch of different types—like differential, density gradient, and continuous flow centrifugation—and each has its own perks depending on what you’re trying to do. For example, differential centrifugation is great for separating parts of cells, while density gradient ones help purify specific cell types or biomolecules based on how dense they are. Then there’s continuous flow centrifugation, which is really catching on in industry because it’s efficient and can process large batches of samples pretty quickly.

Here at Zhejiang Pushkang Biotechnology Co., Ltd., we’re all about using centrifugal microfluidics to develop innovative in vitro diagnostic products. We started back in 2014, and ever since, our team has been pretty focused on R&D—working with advanced centrifugation techniques to create point-of-care testing solutions for all kinds of medical needs, like coagulation and molecular diagnostics. We’re constantly tweaking our centrifugation methods to make tests more accurate and faster, because these days, people really need quick and reliable healthcare options, right? Our goal is to keep pushing the envelope so that healthcare professionals and patients get the best tools available.”

Centrifugation Techniques in Modern Industry

Impact of Centrifugation on Quality Control in Food Production

Centrifugation might sound like a fancy scientific word, but it actually plays a pretty big role in making sure our food stays safe and tasty. Basically, by spinning mixtures at high speeds, manufacturers can separate out different components more easily. This not only helps improve things like texture and flavor but is also super important for safety—making sure any unwanted contaminants are removed. Take dairy, for example: centrifuges help strip cream from milk, which results in better quality products like yogurt and cheese that we all enjoy.

A few tips if you're dealing with centrifugation: First off, make sure your machines are regularly calibrated so they work just right; otherwise, you might not get a good separation. Also, keep an eye on the temperature during the process because sensitive foods can be affected if it gets too hot or cold. And finally, tweak the centrifuge settings depending on what food you’re processing—this way, you get the best yield without sacrificing quality.

All in all, centrifugation isn’t just about separating stuff. It’s part of a bigger system that guarantees our food is safe, high-quality, and meets those strict safety standards we expect. As the food industry keeps evolving, adopting newer, smarter centrifugation methods will be key to consistently delivering great products that people love.

Innovation in Centrifugation Technology: Trends and Future Directions

Innovation in centrifugation tech is really changing the game across modern industries, especially in in-vitro diagnostics (IVD). From what recent reports are saying, the global market for centrifuge equipment could hit around $5.3 billion by 2027 — quite a leap, driven by a growing need for advanced medical tests and biopharma stuff. Zhejiang Pushkang Biotechnology Co., Ltd., is actually right at the forefront of microfluidics, and we’re pretty excited about the role we’ll play in this growth. Our focus on R&D has helped us develop innovative point-of-care testing (POCT) solutions that make coagulation tests, biochemistry, chemiluminescence immunoassays (CLIA), and molecular diagnostics faster, more accurate, and just plain better.

With microfluidic tech — especially centrifugation systems — constantly evolving, we're seeing big shifts across lots of fields. These advancements aren’t just making lab work more efficient; they’re also cutting down on sample sizes and speeding things up. Imagine, some integrated centrifuge systems connected with automation can give you results in just half an hour — that’s a huge improvement compared to traditional methods. As Pushkang keeps pushing the boundaries here, our goal is to help healthcare providers get quick, reliable results, which ultimately means better care for patients in this fast-changing medical landscape.

Environmental Considerations in Industrial Centrifugation Practices

You know, when we talk about industrial centrifugation and its impact on the environment, it’s pretty clear how big of a deal it really is—especially in fields like biotech and food production. As more people become aware of how waste disposal affects our planet, industries are starting to pay more attention to sustainable practices. Recent research even points out the risks involved with improperly handling drilling fluid waste, and how smarter treatment methods can make a difference. These studies really underscore the importance of adopting eco-friendly centrifugation techniques to help reduce environmental harm.

At Zhejiang Pushkang Biotechnology Co., Ltd., they’re doing their part by focusing on centrifugal microfluidics tech—aligned with these green goals. They develop point-of-care testing (POCT) products that use centrifugal methods, which not only make operations more efficient but also cut down on environmental impact. Their efforts in improving energy use and resource recovery show a pretty solid understanding that industrial processes need to get a lot more sustainable.

As we move toward a future where industries and cities work more hand-in-hand, embracing eco-friendly centrifugation practices is gonna be key if we want to keep our planet in balance and use resources wisely.

Enhancing Animal Health: The Role of the Veterinary Immunofluorescence Analyzer MF100V in Diagnostics

The veterinary immunofluorescence analyzer MF100V represents a significant advancement in the realm of animal health diagnostics. This cutting-edge instrument is designed for in vitro diagnostic use, making it an ideal choice for various medical institutions, including central laboratories, emergency labs, and clinical departments. With its compact design, the MF100V can adapt to diverse healthcare settings, providing veterinarians and lab technicians with a reliable tool to enhance diagnostic capabilities.

One of the standout features of the MF100V is its quick turnaround time, delivering results in as fast as three minutes. This efficiency not only reduces waiting time for pet owners but also improves the overall detection efficiency, enabling timely medical interventions. The analyzer also simplifies operations with its plug-and-test functionality, making it user-friendly for professionals in busy environments. Furthermore, the ability to store reagents at room temperature significantly extends their shelf life and maintains performance, minimizing waste and ensuring optimal functionality.

Incorporating the MF100V into veterinary practices can significantly enhance diagnostic accuracy and speed, ultimately improving animal health outcomes. As the demand for rapid and reliable diagnostic tools continues to grow, instruments like the MF100V are poised to play a crucial role in modern veterinary medicine.

FAQS

: Centrifugation is crucial for efficiently separating liquids, solids, and gases in various industries, enhancing product purity and quality.

In pharmaceuticals, centrifugation isolates viable cells from culture media and is integral to ensuring drug production meets stringent safety standards.

In the food industry, centrifugation separates cream from milk and clarifies juices, which improves product quality and shelf life.

To improve effectiveness, optimize speed and time parameters for specific materials, maintain regular equipment maintenance, and consider temperature sensitivity.

Regular maintenance ensures that rotors and tubes are free from debris and wear, which is vital for operational efficiency and safety in separation processes.

Some materials can be thermally sensitive, so cooling techniques should be implemented to maintain stability and preserve the integrity of separated components.

Factors include rotor speed, capacity, sample types, and regular calibration to ensure consistent performance and reliable results.

They have integrated advanced centrifugation techniques into their point-of-care testing products to enhance quality, efficacy, and rapid diagnosis in healthcare.

It ensures high precision and speed in separating blood components, purifying proteins, and concentrating samples, leading to accurate test results.

High speeds can lead to quicker separation but may also damage sensitive components, so it's essential to find the right balance for the materials being processed.

Conclusion

Centrifugation is pretty much a cornerstone in a lot of industrial separation processes. It's a game-changer when it comes to boosting efficiency and getting things just right across different sectors. Think about industries like pharma — centrifuges are absolutely vital for isolating specific compounds and preparing samples for the next step in analysis. When you compare various centrifugation methods, you start seeing how versatile they can be — from sorting blood components in medical labs to clearing out fermentation broths in biotech setups.

And let's not forget how important centrifugation is for quality control in food production. It helps remove impurities, making sure products are safe and top-notch. Companies like Zhejiang Pushkang Biotechnology are actually pushing the envelope by using centrifugal microfluidics for point-of-care testing, which is pretty cool. Looking ahead, it seems like centrifugation technology is heading toward more automation and greener practices — all of which just underlines how essential it is in today’s industries.

Related Posts

-

5 Key Reasons Veterinary Care is Essential for Your Pet's Health and Wellbeing

-

Comprehensive Guide to Understanding For In Vitro Diagnostic Use Only Regulations and Standards

-

Mastering the Rcf Centrifuge A Step by Step Tutorial for Optimal Performance

-

Ultimate Guide to Understanding Point Of Care Testing and Its Impact on Healthcare